forklift test questions and answers pdf

Forklift Test Questions and Answers PDF: A Comprehensive Study Plan

Embark on a journey to forklift mastery! This PDF resource delivers vital questions, answers, and guides, preparing you for certification and a safer workplace.

Forklift certification is a crucial process ensuring operators possess the knowledge and skills for safe and efficient operation. This isn’t merely about maneuvering machinery; it’s about understanding load dynamics, workplace hazards, and adhering to stringent safety regulations like those set by OSHA. A comprehensive understanding, often assessed through written and practical tests, is paramount.

The certification journey typically begins with theoretical training, covering topics from forklift types and stability to fueling procedures and pedestrian safety. Following this, a practical assessment evaluates the operator’s ability to perform pre-operational inspections, maneuver loads effectively, and demonstrate safe operating practices. Successful completion grants a license or certification, validating competency and minimizing workplace accidents. Resources like practice tests and PDF study guides are invaluable preparation tools.

Importance of Forklift Operator Training

Proper forklift operator training is absolutely vital for workplace safety and legal compliance. Untrained operators pose significant risks – to themselves, colleagues, and property – leading to costly accidents, injuries, and potential legal ramifications. Comprehensive training equips operators with the knowledge to understand load centers, stability triangles, and safe operating procedures.

Beyond safety, training boosts efficiency and reduces damage to goods and equipment. Certified operators are more adept at maneuvering in tight spaces, handling diverse loads, and adhering to workplace protocols. Investing in training demonstrates a commitment to employee well-being and responsible operations. Utilizing resources like practice quizzes and detailed PDF guides reinforces learning and prepares individuals for successful certification assessments, ultimately fostering a safer and more productive work environment.

Types of Forklift Licenses & Certifications

Forklift certifications aren’t universally standardized; requirements vary based on location and the type of forklift used. OSHA in the US mandates training but doesn’t issue licenses directly. Instead, employers are responsible for ensuring operators are properly trained and evaluated. Common certifications include those offered by organizations aligned with ANSI standards, demonstrating competency in safe operation.

Different forklift classes – electric, internal combustion, rough terrain – may necessitate specific training modules. Renewal is typically required every three years, reinforcing knowledge and updating operators on new safety regulations. Preparing for certification involves studying comprehensive materials, practicing with sample test questions, and successfully completing both written and practical assessments. PDF study guides and online practice tests are invaluable resources for achieving certification.

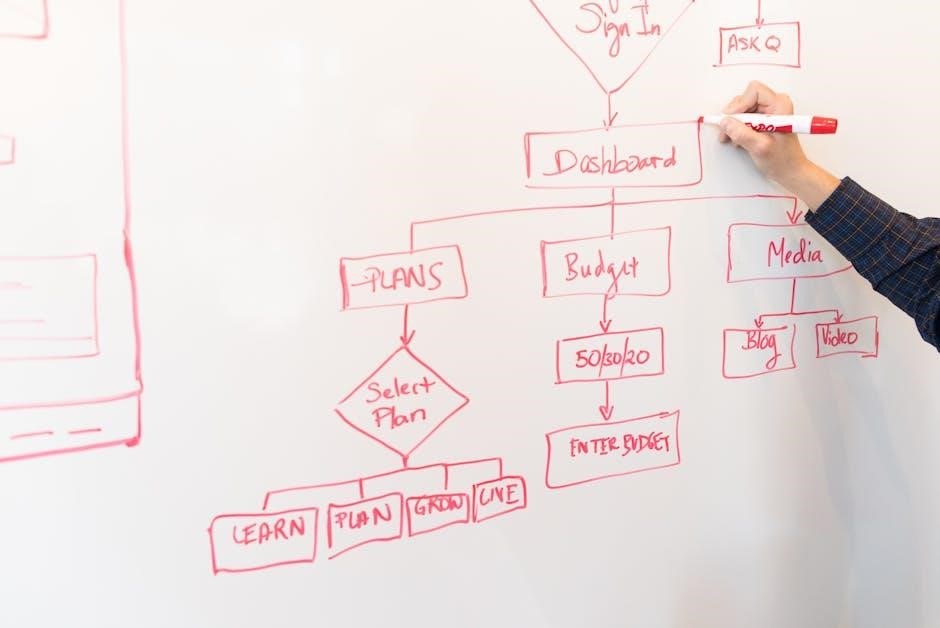

Understanding the WSSCA Written Test

The WSSCA Written Test, a crucial component of forklift operator certification, assesses knowledge of safety protocols and operational guidelines. This assessment evaluates understanding of load handling, stability principles, and workplace regulations. Questions often cover topics like load center calculation, forklift stability triangle, and proper fueling procedures. Thorough preparation is key to success, utilizing resources like PDF study guides and online practice tests.

The test format typically consists of multiple-choice questions designed to gauge comprehension of essential concepts. Familiarizing yourself with common question types and reviewing relevant OSHA standards is highly recommended. Passing the WSSCA written exam is a prerequisite for the practical evaluation, demonstrating a foundational understanding of safe forklift operation.

Key Areas Covered in Forklift Certification Tests

Forklift certification tests comprehensively evaluate operator knowledge across several critical areas. Expect questions focusing on load handling and stability, including load center calculations and understanding the stability triangle. Fueling procedures, encompassing safe practices for propane and battery-powered forklifts, are also heavily tested; A significant portion assesses adherence to OSHA forklift standards and workplace safety protocols.

Tests delve into pre-operational inspection procedures, ensuring operators can identify potential mechanical issues. Maneuvering skills and proper load placement techniques are evaluated, both theoretically and practically. Understanding legal ramifications of operating without certification and employer responsibilities are also key components. Preparation should include reviewing relevant PDF guides and utilizing online practice tests to reinforce learning.

Load Handling and Stability

Mastering load handling is paramount for safe forklift operation. Certification tests heavily emphasize understanding load centers – the distance from the fork face to the load’s center of gravity – and its impact on stability. Operators must demonstrate knowledge of how uneven loads or improperly distributed weight affect forklift balance, increasing tip-over risks.

Questions will assess your ability to determine safe load capacities based on load weight and the forklift’s load chart. Proper stacking techniques, securing loads, and avoiding exceeding the forklift’s rated capacity are crucial. Maintaining a low center of gravity and understanding the forklift’s stability triangle are essential for preventing accidents and ensuring a secure working environment.

Load Center Calculation

Accurate load center calculation is fundamental to forklift safety and operational efficiency. Tests frequently present scenarios requiring you to determine the load center distance – measured from the fork face to the load’s center of gravity. This calculation directly impacts the forklift’s capacity; a further load center reduces the weight the forklift can safely lift.

Expect questions involving measuring load dimensions and estimating the center of gravity. Understanding how load center affects stability is vital, as improper calculations can lead to tip-overs. Practice applying the formula and interpreting load charts. Mastering this skill ensures operators prioritize safe lifting practices and avoid exceeding the forklift’s rated capacity, safeguarding both personnel and materials.

Forklift Stability Triangle

The forklift stability triangle is a core concept in operator training and a frequent topic on certification exams. This imaginary triangle, formed by the front wheels and the center of gravity, dictates the forklift’s stability. Questions will assess your understanding of how load weight, load center, and forklift configuration affect this triangle.

A stable forklift maintains its center of gravity within the triangle’s boundaries. Factors like uneven surfaces, excessive speed, and improper load handling can shift the center of gravity, causing instability and potential tip-overs. Expect test questions requiring you to visualize how different scenarios impact the triangle and predict resulting stability changes. Comprehending this principle is crucial for safe operation.

Forklift Safety Regulations

Forklift safety regulations are paramount for preventing accidents and ensuring a secure work environment, heavily emphasized in certification tests. These rules, often derived from OSHA standards and approved codes, cover a wide range of operational aspects, from pre-operational inspections to load handling procedures and pedestrian awareness.

Test questions frequently assess your knowledge of these regulations, including proper signaling, speed limits, and restrictions on load heights. Understanding the legal ramifications of non-compliance is also vital. Expect scenarios requiring you to identify safety violations and propose corrective actions. Familiarity with workplace safety protocols and adherence to established guidelines are key to passing your exam and operating safely.

OSHA Forklift Standards

The Occupational Safety and Health Administration (OSHA) sets the benchmark for forklift operation safety in the United States, and understanding these standards is crucial for certification. Forklift test questions heavily emphasize OSHA’s requirements regarding operator training, certification, and workplace safety protocols.

Expect questions covering topics like load capacity limits, proper fueling procedures, and the mandatory use of personal protective equipment (PPE). OSHA standards also dictate the frequency and scope of forklift inspections, as well as the procedures for reporting accidents and near misses. Demonstrating a thorough grasp of these regulations is essential for passing your forklift certification exam and maintaining a safe working environment.

Workplace Safety Protocols

Beyond OSHA regulations, each workplace establishes specific safety protocols for forklift operation, and test questions frequently assess your knowledge of these site-specific rules. Expect inquiries about pedestrian traffic management, designated forklift travel lanes, and speed limits within the facility. Understanding proper communication signals, such as horn usage and hand gestures, is also vital.

Forklift test preparation should include a review of your employer’s safety manual and participation in site-specific training. Questions may address emergency procedures, load handling in congested areas, and the correct methods for stacking and unstacking materials. Prioritizing workplace safety demonstrates responsible operation and contributes to a hazard-free environment.

Common Forklift Test Questions ー Multiple Choice

Multiple-choice questions dominate forklift certification tests, evaluating your understanding of core principles. Expect scenarios testing load capacity calculations, proper fueling procedures (including battery charging safety), and stability concepts. Questions frequently assess your knowledge of the forklift stability triangle and the impact of load center on safe operation.

Practice tests often include questions about pre-operational inspection procedures, identifying potential hazards, and responding to emergency situations. Familiarize yourself with common terminology and OSHA regulations. Mastering these multiple-choice formats is crucial for success, ensuring you can quickly and accurately apply safety knowledge.

Questions on Load Capacity

Load capacity questions are fundamental to forklift certification, testing your ability to determine safe lifting limits. Expect scenarios requiring you to calculate load weights, considering factors like load center and forklift capacity plates. Questions will assess your understanding of how exceeding capacity impacts stability and increases tip-over risk.

You’ll encounter problems involving load distribution, attachment usage, and the effects of lifting loads at different heights. Understanding the relationship between load weight, load center, and the forklift’s stability triangle is vital. Correctly interpreting capacity charts and applying this knowledge in practical situations is key to passing the exam.

Questions on Fueling Procedures

Fueling procedure questions emphasize safety protocols for both propane (LP gas) and electric forklifts. Expect inquiries about proper personal protective equipment (PPE), ventilation requirements, and leak detection methods during refueling. Questions will cover the correct procedures for connecting and disconnecting fuel tanks, as well as emergency shutdown procedures in case of a fuel spill or leak.

For electric forklifts, questions will focus on battery charging safety, including proper ventilation, electrolyte handling, and the use of designated charging areas. Understanding the risks associated with hydrogen gas buildup during charging is crucial. You’ll be tested on recognizing and responding to abnormal charging conditions, ensuring a safe fueling environment.

Practical Forklift Assessment Procedures

The practical assessment rigorously evaluates your operational skills in a controlled environment. Expect a pre-operational inspection, demanding a thorough check of all safety features – tires, forks, lights, and fluid levels. Maneuvering skills are heavily scrutinized, including navigating tight spaces, precise load handling, and controlled stopping.

Evaluators observe adherence to safety regulations throughout the assessment. Proper lifting techniques, load stability checks, and pedestrian awareness are paramount. You’ll demonstrate skills like stacking, unstacking, and transporting loads safely and efficiently. Failure to follow procedures or demonstrate safe operation will result in deductions, potentially leading to assessment failure.

Pre-Operational Inspection Checklist

A meticulous pre-operational inspection is crucial for safe forklift operation and a key component of any certification assessment. Begin with checking fluid levels – oil, coolant, brake fluid, and hydraulic fluid – ensuring they are within acceptable ranges. Inspect the tires for wear, damage, and proper inflation. Thoroughly examine the forks for cracks, bends, or any signs of structural weakness.

Test the functionality of all safety devices: seatbelt, horn, lights, and backup alarm. Verify the steering and braking systems respond correctly. Document any deficiencies found during the inspection and report them immediately. A completed checklist demonstrates diligence and commitment to safety, vital for passing the practical exam.

Maneuvering and Load Placement Skills

Demonstrating proficient maneuvering and precise load placement is paramount during the practical forklift assessment. Examiners evaluate your ability to navigate tight spaces, execute smooth turns, and maintain control at varying speeds. Proper load handling involves lifting, tilting, and lowering loads smoothly and safely, avoiding sudden movements.

Accurate load placement requires aligning the load with the designated location, ensuring stability, and avoiding obstructions. Maintaining a safe distance from pedestrians and other obstacles is critical. Skillful maneuvering showcases your understanding of forklift dynamics and commitment to a secure work environment, directly impacting your certification outcome.

Resources for Forklift Test Preparation

Comprehensive preparation is key to passing your forklift certification exam. Numerous resources are available, including free online practice tests designed to familiarize you with question formats and key concepts. These tests offer immediate feedback, highlighting areas needing improvement.

PDF study guides and manuals provide in-depth coverage of forklift operation, safety regulations, and load handling techniques. Look for materials aligned with WSSCA standards. Jim Cook’s resources offer a practice exam mirroring the official course content. Utilizing a combination of these tools – practice tests, detailed guides, and official course materials – will significantly boost your confidence and increase your chances of success.

Free Online Practice Tests

Accessing free online practice tests is a smart strategy for forklift certification preparation. These tests simulate the real exam environment, allowing you to assess your knowledge of crucial safety protocols and operational guidelines. They cover essential topics like load handling, equipment safety checks, and adherence to workplace regulations.

Many platforms offer immediate scoring and feedback, pinpointing areas where further study is needed. Resources like Jim Cook’s practice exam directly reflect the content from the Forklift Operator Course. Regularly utilizing these tests will not only prepare you for the official certification but also reinforce safe operating habits, contributing to a safer work environment for everyone.

PDF Study Guides and Manuals

Comprehensive PDF study guides and manuals are invaluable tools for forklift certification success. These resources consolidate essential information regarding forklift operation, safety regulations, and the WSSCA written test content. Documents like the “Forklift Safety and Operation Guide” provide detailed explanations of procedures and best practices.

Furthermore, “Forklift Practical Training and Assessment Procedures” PDFs offer insights into the practical evaluation process. Utilizing these materials allows for focused self-study, reinforcing understanding of load capacity, fueling procedures, and stability principles. Accessing these guides ensures you’re well-prepared to demonstrate competency and pass both the written and practical components of your certification.

Avoiding Common Forklift Accidents

Proactive accident prevention is paramount in forklift operation. Understanding potential hazards, like tip-overs, is crucial, and training quizzes reinforce safe practices. Maintaining awareness of pedestrian traffic and adhering to workplace safety protocols significantly reduces risk. Proper load handling, including accurate load center calculations and respecting load capacity limits, are fundamental.

Regular pre-operational inspections, as outlined in checklists, identify mechanical issues before they escalate. Thorough knowledge of OSHA forklift standards and employer responsibilities contributes to a safer environment. By prioritizing safety and utilizing available resources, operators can minimize the likelihood of incidents and ensure a secure workplace for everyone.

Preventing Tip-Overs

Forklift stability hinges on understanding the stability triangle and load center. Exceeding load capacity or improperly positioning loads dramatically increases tip-over risk. Always travel with the load tilted back slightly to improve stability, and avoid sharp turns at high speeds. Uneven surfaces and sudden stops also contribute to instability, demanding cautious operation.

Regular training, reinforced by practice tests, emphasizes these critical safety principles. Maintaining a slow and controlled speed, especially when loaded, is essential. Proper load handling techniques, including securing the load and distributing weight evenly, are vital preventative measures. Prioritizing these practices ensures a safer operating environment and minimizes potential accidents.

Pedestrian Safety Around Forklifts

Prioritizing pedestrian safety is paramount when operating a forklift. Always be aware of your surroundings and yield to pedestrians. Utilize the horn to alert individuals to your presence, especially at intersections and blind spots. Maintain a safe distance and never assume pedestrians see or hear you.

Comprehensive forklift training, including practice tests, stresses the importance of clear communication and cautious maneuvering. Designated pedestrian walkways and barriers enhance safety, minimizing interaction with forklift traffic. Employers must enforce strict safety protocols and provide adequate lighting. Remember, a proactive approach to pedestrian safety prevents accidents and fosters a secure work environment.

Consequences of Operating Without Certification

Operating a forklift without proper certification carries significant repercussions. Immediate termination of employment is a common consequence, alongside the invalidation of any insurance coverage in the event of an accident. Legal ramifications, including substantial fines and potential criminal charges, can arise from non-compliance with OSHA standards.

Furthermore, uncertified operation dramatically increases the risk of workplace accidents, leading to injuries or fatalities. Thorough forklift training, reinforced by practice tests and quizzes, is crucial for mitigating these risks. Employers have a legal and ethical responsibility to ensure all operators are adequately trained and certified, safeguarding both employees and the organization.

Legal Ramifications

The legal consequences of operating a forklift without certification are substantial and far-reaching. OSHA (Occupational Safety and Health Administration) enforces strict regulations regarding forklift operation, and violations can result in hefty fines for employers – potentially exceeding tens of thousands of dollars per infraction. Beyond financial penalties, employers may face civil lawsuits stemming from accidents caused by uncertified operators;

Individuals operating forklifts illegally could be held personally liable for damages and injuries. Criminal charges are also possible in cases of gross negligence or willful disregard for safety regulations. Maintaining comprehensive records of operator training and certification is vital for demonstrating compliance and mitigating legal risks.

Employer Responsibilities

Employers bear a significant responsibility for ensuring the safe operation of forklifts within their facilities. This includes providing comprehensive forklift operator training and certification programs that meet OSHA standards. Regular refresher training is crucial, as is the evaluation of operator performance to identify and address any skill deficiencies.

Maintaining a safe working environment necessitates thorough workplace inspections to identify and mitigate potential hazards. Employers must also enforce strict adherence to safety protocols, including load capacity limits and pedestrian safety rules. Proper documentation of all training, evaluations, and maintenance activities is essential for demonstrating compliance and protecting the organization from legal repercussions.