ultrasound guided iv insertion training for nurses

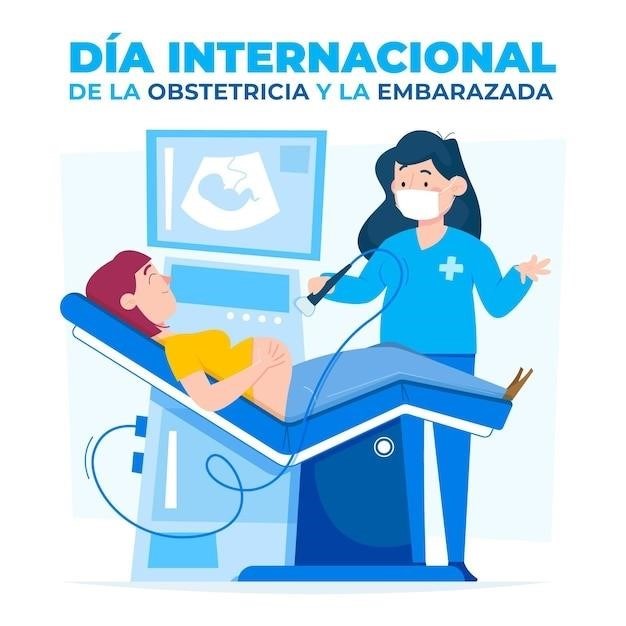

Ultrasound-Guided IV Insertion Training for Nurses

Ultrasound-guided intravenous (IV) insertion training for nurses is becoming increasingly common, with numerous studies demonstrating its effectiveness in improving success rates, reducing complications, and enhancing nurse confidence. Training programs typically cover topics such as ultrasound equipment, vessel identification, catheter selection, and insertion techniques. The training involves both theoretical instruction and practical skills training, often using simulation models and real-world practice scenarios.

Introduction

Ultrasound-guided intravenous (IV) insertion is a rapidly evolving technique that has revolutionized the way nurses approach vascular access. This procedure involves using ultrasound imaging to visualize blood vessels, enabling precise and safe needle placement for IV catheterization. The use of ultrasound guidance has significantly enhanced the accuracy and safety of IV insertion, leading to improved patient outcomes and reduced complications; This article explores the importance of ultrasound-guided IV insertion training for nurses, examining its benefits, training programs, and clinical applications.

The Need for Ultrasound-Guided IV Insertion

The need for ultrasound-guided IV insertion arises from the challenges associated with traditional IV access techniques. Many patients, especially those with difficult IV access, often require multiple attempts, leading to discomfort, anxiety, and potential complications. Ultrasound-guided IV insertion addresses these challenges by providing a more accurate and efficient method for obtaining vascular access. Studies have consistently shown that ultrasound guidance significantly improves success rates, reduces the number of attempts, and minimizes the risk of complications such as extravasation, hematoma formation, and nerve injury.

Difficult IV Access

Difficult IV access is a common challenge faced by healthcare professionals, particularly in emergency settings. Patients with conditions such as obesity, dehydration, or peripheral vascular disease often present with small, deep, or rolling veins, making traditional IV insertion techniques difficult and potentially unsuccessful. These patients may require multiple attempts, leading to increased pain, anxiety, and even tissue damage. Ultrasound-guided IV insertion provides a solution by visualizing the veins in real-time, allowing practitioners to identify suitable vessels and accurately place the IV catheter on the first attempt, minimizing discomfort and complications.

Improved Success Rates

Ultrasound-guided IV insertion has been shown to significantly improve success rates compared to traditional methods. Studies have demonstrated that ultrasound guidance increases the likelihood of successful IV placement on the first attempt, reducing the need for multiple sticks and the associated discomfort and complications. This is particularly relevant for patients with difficult IV access, where traditional methods often result in lower success rates. By providing a clear visualization of the veins, ultrasound guidance allows practitioners to choose the most appropriate vessel and guide the needle precisely, leading to a higher probability of successful IV insertion.

Reduced Complications

Ultrasound-guided IV insertion plays a crucial role in reducing complications associated with IV access. Traditional methods often involve multiple attempts, which can lead to hematomas, nerve damage, and infiltration. Ultrasound guidance, by providing a clear visualization of the vein and surrounding tissues, allows practitioners to avoid these complications. The precise placement of the needle, guided by ultrasound imaging, minimizes the risk of damaging surrounding structures. This enhanced accuracy and precision are particularly important for patients with fragile veins, obese individuals, or those with difficult vascular access, where traditional methods pose a greater risk of complications.

Benefits of Ultrasound-Guided IV Insertion

Ultrasound-guided IV insertion offers numerous benefits for both patients and healthcare providers. By providing a clear visualization of the vein and surrounding tissues, ultrasound guidance enhances accuracy and safety, reducing the risk of complications such as hematomas, nerve damage, and infiltration. The procedure also minimizes patient discomfort, as the needle can be inserted with greater precision and fewer attempts. Furthermore, ultrasound-guided IV insertion improves nurse confidence, allowing them to perform the procedure with greater skill and efficiency. This increased confidence can lead to better patient outcomes and a more positive experience for both the nurse and the patient.

Enhanced Accuracy and Safety

Ultrasound-guided IV insertion significantly enhances accuracy and safety by providing real-time visualization of the vein and surrounding tissues. This allows nurses to accurately identify the optimal vein for insertion, avoiding potential complications associated with blind insertion. The ultrasound image guides the needle placement, minimizing the risk of missing the vein, causing hematomas, or damaging surrounding nerves. The use of ultrasound also facilitates the identification of potential anatomical variations, ensuring that the procedure is performed safely and effectively. This enhanced accuracy and safety contribute to improved patient outcomes and a reduced risk of complications.

Reduced Patient Discomfort

Ultrasound-guided IV insertion significantly reduces patient discomfort compared to traditional blind insertion methods. The ultrasound image provides clear visualization of the vein and surrounding tissues, enabling nurses to accurately target the vein and minimize the number of attempts required for successful insertion. This reduces the risk of multiple needle sticks, which can be painful and cause bruising. Moreover, the use of ultrasound allows for a more gentle and controlled insertion technique, minimizing the risk of nerve damage or other complications that can cause pain and discomfort. By reducing the number of attempts and ensuring a smoother insertion process, ultrasound-guided IV insertion contributes to a more positive patient experience and improved satisfaction.

Improved Nurse Confidence

Ultrasound-guided IV insertion training not only enhances technical skills but also significantly boosts nurses’ confidence in their ability to perform IV insertions. The ability to visualize the vein and surrounding structures using ultrasound provides a clear understanding of the anatomy and allows nurses to approach the procedure with greater certainty. This visual confirmation eliminates the guesswork often associated with traditional blind insertion methods, reducing anxiety and increasing confidence in the procedure’s success. Furthermore, the training provides nurses with the knowledge and skills to handle challenging situations, such as patients with difficult IV access or those requiring specific types of IV lines. This newfound expertise empowers nurses to confidently manage a wider range of IV insertion scenarios, contributing to a sense of accomplishment and professional satisfaction.

Ultrasound-Guided IV Insertion Training Programs

Ultrasound-guided IV insertion training programs are designed to equip nurses with the knowledge and skills necessary to safely and effectively perform ultrasound-guided IV insertions. These programs typically involve a comprehensive curriculum that covers the theoretical and practical aspects of the procedure. The training encompasses topics such as ultrasound equipment operation, anatomy and physiology of the vascular system, identification of vessels and surrounding structures, selecting appropriate catheters, and various insertion techniques. Practical skills training is a crucial component of the program, allowing nurses to practice their skills on simulation models and, in some cases, real patients under supervision. The training programs also emphasize the importance of maintaining sterile technique, managing potential complications, and documenting the procedure.

Course Content

The content of ultrasound-guided IV insertion training programs is designed to provide nurses with a comprehensive understanding of the procedure and the skills necessary to perform it safely and effectively. Course content typically includes a combination of theoretical and practical instruction. Theoretical instruction covers topics such as ultrasound physics and equipment, anatomy and physiology of the vascular system, identification of vessels and surrounding structures, selecting appropriate catheters, and various insertion techniques. Practical skills training involves hands-on practice using simulation models and, in some cases, real patients under supervision. The course also covers the importance of maintaining sterile technique, managing potential complications, and documenting the procedure.

Practical Skills Training

Practical skills training is an essential component of ultrasound-guided IV insertion training programs. It provides nurses with the opportunity to apply the theoretical knowledge they have learned in a hands-on setting. Practical skills training typically involves using simulation models that mimic the anatomy and physiology of the vascular system. These models allow nurses to practice identifying vessels, selecting appropriate catheters, and performing the insertion procedure under simulated conditions. Some programs also offer real-world practice scenarios, where nurses can practice under the supervision of experienced clinicians. This practical experience allows nurses to develop the necessary dexterity and confidence to perform ultrasound-guided IV insertions safely and effectively.

Simulation and Real-World Practice

Simulation and real-world practice are integral components of ultrasound-guided IV insertion training programs. Simulation allows nurses to practice their skills in a controlled environment without the risks associated with real patients. Simulation models provide a realistic representation of anatomy and physiology, allowing nurses to practice identifying vessels, selecting appropriate catheters, and performing the insertion procedure. Real-world practice provides nurses with the opportunity to apply their skills in a clinical setting under the supervision of experienced clinicians. This practical experience allows nurses to gain confidence and proficiency in performing ultrasound-guided IV insertions in a variety of clinical situations. By combining simulation and real-world practice, training programs can effectively prepare nurses for the challenges of performing ultrasound-guided IV insertions in a clinical setting.

Clinical Applications of Ultrasound-Guided IV Insertion

Ultrasound-guided IV insertion has proven beneficial in diverse clinical settings, improving patient care and outcomes. In the emergency department, ultrasound guidance aids in securing venous access for critically ill patients, especially those with difficult IV access. This is crucial for prompt administration of medications and fluids. Similarly, in critical care units, ultrasound-guided IV insertion enables the placement of central venous catheters, essential for long-term medication administration and hemodynamic monitoring. Oncology patients often require frequent blood draws and IV medication administration, making ultrasound-guided IV insertion invaluable for minimizing discomfort and maximizing success rates. These applications highlight the versatility and impact of ultrasound-guided IV insertion in enhancing patient care across multiple clinical specialties.

Emergency Department

In the fast-paced and demanding environment of the emergency department, securing venous access for critically ill patients can be a challenge. Ultrasound-guided IV insertion has emerged as a valuable tool for ED nurses, significantly improving success rates and reducing complications. By providing real-time visualization of vessels, ultrasound guidance helps nurses identify suitable veins, even in patients with difficult IV access, such as those with obesity, edema, or prior IV attempts. This enhanced accuracy minimizes the number of attempts, reducing patient discomfort and anxiety. Moreover, ultrasound guidance allows nurses to avoid potentially dangerous areas, such as nerves and arteries, minimizing the risk of complications such as hematomas and nerve injuries. The ability to quickly and safely establish IV access in the emergency department is crucial for delivering timely medical care and improving patient outcomes.

Critical Care

Critical care settings often involve patients with complex medical conditions and compromised vascular access, making ultrasound-guided IV insertion a valuable tool for critical care nurses. The ability to visualize vessels and guide needle placement with precision allows for the establishment of reliable IV access, even in patients with difficult veins or those requiring multiple IV lines. This is particularly crucial for administering medications, fluids, and blood products, as well as for monitoring hemodynamic parameters. Ultrasound guidance helps critical care nurses achieve successful IV access in a timely and safe manner, minimizing complications such as extravasation, hematomas, and nerve damage. This improves patient safety and allows for the effective delivery of critical care interventions, ultimately contributing to better patient outcomes.

Oncology

In oncology, patients often undergo frequent chemotherapy and other treatments that necessitate frequent IV access. Ultrasound-guided IV insertion proves invaluable in this setting, as it allows for precise and safe placement of peripheral IV lines, central venous catheters, and even implanted ports. The use of ultrasound helps nurses navigate complex vascular anatomy, avoiding potential complications such as hematomas, extravasation, and nerve damage, which can be particularly detrimental to patients already undergoing challenging treatments. This technique minimizes patient discomfort and improves the accuracy of medication delivery, ensuring optimal therapeutic outcomes. Furthermore, ultrasound guidance facilitates the identification of suitable veins for IV access, minimizing the need for multiple attempts, especially in patients with compromised vascular access due to chemotherapy or other treatments.

Future Directions in Ultrasound-Guided IV Insertion

The field of ultrasound-guided IV insertion is constantly evolving, driven by advancements in technology and a growing recognition of its benefits. One key area of progress is the development of advanced ultrasound technology, including handheld devices with enhanced image quality and real-time visualization capabilities. These innovations promise to further improve the accuracy and efficiency of IV placement, making it even more accessible and user-friendly for nurses. Another significant development is the integration of ultrasound guidance with electronic medical records (EMRs). This integration streamlines documentation, improves patient safety, and facilitates data analysis for research and quality improvement purposes. Finally, ongoing research and development are crucial for further advancing the practice of ultrasound-guided IV insertion. Researchers are actively exploring new applications, optimizing training methods, and investigating the long-term impact of this technique on patient outcomes.

Advanced Ultrasound Technology

The field of ultrasound technology is continuously evolving, leading to the development of advanced devices specifically designed for ultrasound-guided IV insertion. These innovations aim to enhance image quality, improve visualization, and streamline the process for nurses. Handheld ultrasound scanners are becoming increasingly popular due to their portability and ease of use. These devices offer real-time imaging, allowing nurses to visualize vessels and guide the needle with greater precision. Additionally, advancements in image processing and software algorithms are leading to clearer and more detailed images, making it easier for nurses to identify the optimal vein for insertion. The development of 3D ultrasound technology also holds promise for the future, enabling a more comprehensive view of the anatomy and facilitating even more accurate needle placement. These advancements in ultrasound technology are poised to revolutionize the practice of ultrasound-guided IV insertion, making it more accessible, efficient, and effective for nurses.

Integration with Electronic Medical Records

The integration of ultrasound-guided IV insertion with electronic medical records (EMRs) holds significant potential to enhance patient care and streamline workflows. By seamlessly connecting ultrasound data with patient records, nurses can access vital information about the patient’s vascular anatomy, previous IV access attempts, and any relevant medical history. This integration allows for more informed decision-making during the IV insertion process, reducing the risk of complications and improving the overall patient experience. Furthermore, real-time data capture and documentation within the EMR can eliminate the need for separate charting, saving time and reducing the risk of errors. The integration of ultrasound-guided IV insertion with EMRs can also facilitate data analysis and research, allowing healthcare professionals to track outcomes, identify trends, and improve the overall efficacy of the procedure. This integration is expected to play a pivotal role in the future of ultrasound-guided IV insertion, creating a more efficient and data-driven approach to patient care.

Research and Development

Ongoing research and development in ultrasound-guided IV insertion are focused on improving the technology, expanding its clinical applications, and enhancing training methodologies. Researchers are actively investigating the use of advanced ultrasound technology, such as 3D imaging and artificial intelligence, to further enhance the accuracy and safety of IV insertion. Studies are also exploring the development of new ultrasound-guided devices, such as needle-guidance systems and automated vein finders, to simplify the procedure and minimize the need for manual manipulation. Furthermore, researchers are working to create more effective training programs, incorporating virtual reality simulations and gamification techniques to enhance the learning experience and improve the transfer of skills to real-world practice. The continuous advancement of research and development in this field will play a crucial role in shaping the future of ultrasound-guided IV insertion, leading to better patient outcomes, improved nurse proficiency, and a more efficient and effective approach to vascular access.